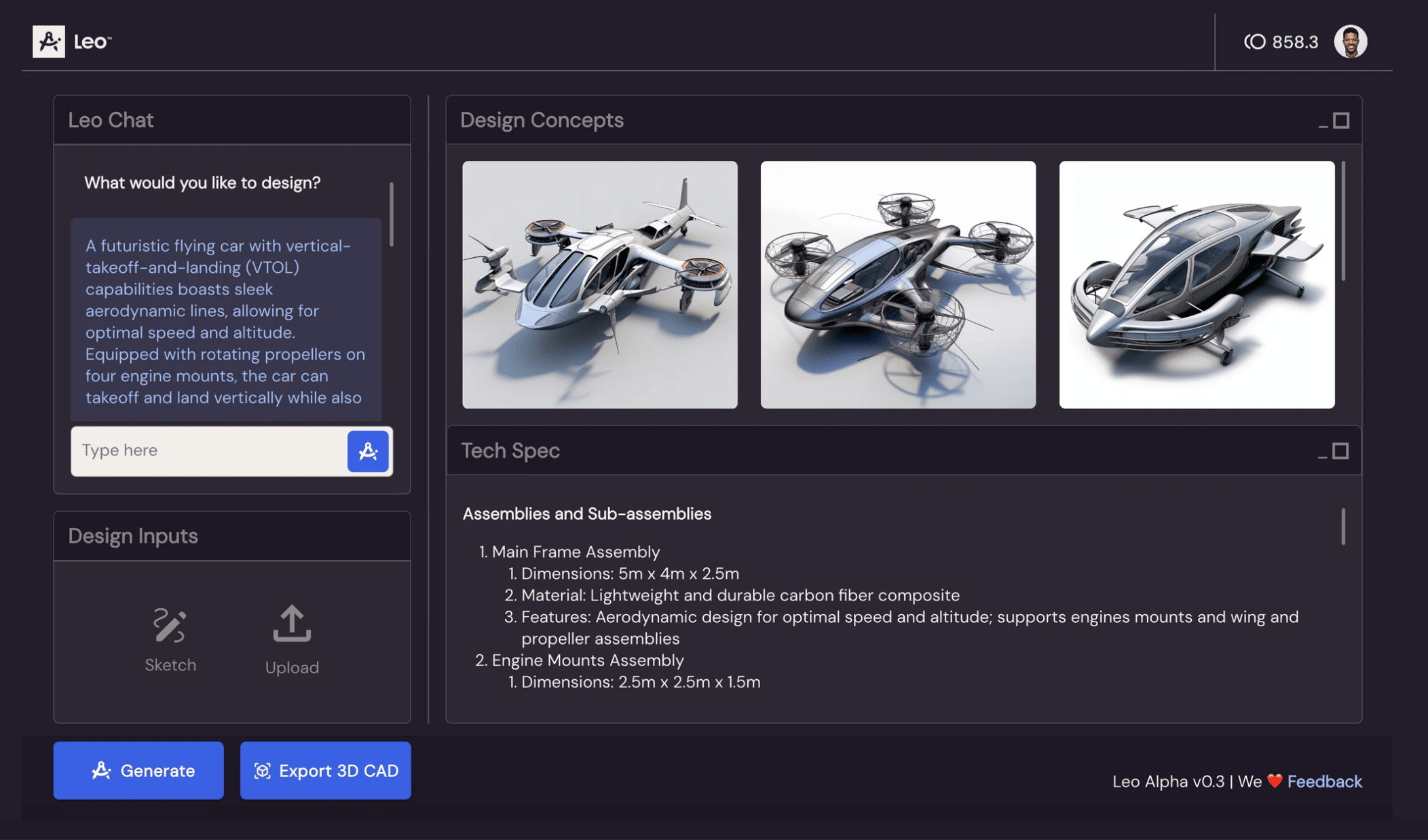

Introducing Leo™, a groundbreaking engineering design copilot that is revolutionizing the way engineers and designers work.

As the world’s first of its kind, Leo harnesses the power of generative AI to rapidly convert text descriptions, rough sketches, detailed specifications, and stringent CAD constraints into fully optimized, ready-to-manufacture 3D CAD models.

This innovative tool significantly enhances productivity by automating the most time-consuming aspects of the design process.

With Leo™, the transformation from concept to a detailed design doesn’t just get faster—it becomes more efficient.

By incorporating design for manufacturing and assembly (DFMA) principles right from the start, Leo ensures that the generated models are not only innovative but also perfectly aligned with manufacturing requirements.

This integration dramatically reduces the need for redesigns and adjustments, cutting down the engineering time and costs by up to 70%.

Leo™ is particularly beneficial for industries where speed, accuracy, and cost-efficiency are paramount.

It enables rapid prototyping and iterative design, allowing for quick adjustments based on real-world testing and feedback.

This agility is essential in today’s fast-paced market, providing a significant competitive edge to businesses across various sectors.

Whether you are refining a complex aerospace component or designing consumer electronics, Leo™ offers a seamless, intuitive interface that makes it accessible to professionals at all levels.

For engineers and designers looking to expediece their design process, ensure precision, and cut costs, Leo™ is an indispensable tool.

By transforming how products are designed, Leo™ is not just a software application—it’s an essential partner in innovation.